2. Painting Products

Kayvee Sales Corporation offer wide range of Painting Products which includes - Touch up Paint & Touch up Spray Gun, Repair Putty & Zinc Spray etc.

Features: Accurate composition, High effectiveness, Quality tested, Excellent adhesive strength, Better glaze, Fine finish, Excellent spraying, Complete tested, Prevents corrosion, Sturdy construction, Ergonomic design and Light weight etc.

2.1 TAK PEELABLE - Coating for Paint Spray Booth Walls

TAK PEELABLE is white pigmented water based peelable protective coating. It is developed for application to paint spray booth walls and panels. this endures the overspread paint deposits to be removed quickly and easily with less labour and time.

TAK PEELABLE is white pigmented water based peelable protective coating. It is developed for application to paint spray booth walls and panels. this endures the overspread paint deposits to be removed quickly and easily with less labour and time.

Applications: TAK PEELABLE is applied by brush or by conventional spary equipment. Since the supply viscosity is adjusted for spraying purpose, TAK PEELABLE should be used as supplied. Ensures that spray equipment is washed with water before use and is free of solvent, thinners etc. which will cause coagulation of the TAK PEELABLE. The spraying of TAK PEELABLE can be done with spray gun nozzle of 1.5 to 2 mm diameter. Air pressure should be according to normal paint spraying method. The film thickness of around 100 microns is recommended to achieve good peeling properties of TAK PEELABLE 3-4 coats at interval of 3-4 hours may be required to achieve expected film thickness. Normally drying time is 4 hours to 6 hours with good air circulation at room temperature. Expected coverage is 2-3 squre meter per kilogram.

The TAK PEELABLE coating, which has the following benefits.

2.2 BOOTH ADDITIVE - For Chemical Treatment of Over Sprayed Paint

The BOOTH ADDITIVE formulated so as to widen its range of applicability with respect to types of booths. This means that the paint is denatured to the required extent to enable it to be floated or sunk, according booth design, with minimum adhesion of paint residues to surface washed by the additive solution. Product recommended for no pump, low volume paint consuption.

The BOOTH ADDITIVE formulated so as to widen its range of applicability with respect to types of booths. This means that the paint is denatured to the required extent to enable it to be floated or sunk, according booth design, with minimum adhesion of paint residues to surface washed by the additive solution. Product recommended for no pump, low volume paint consuption.

Operation: The system consists of single component powder based formulation, which is dosed into the water of the spray booth and on dissolving pH of water raises above 9 to give efficient performance.

Initial Charge: For introduction of BOOTH ADDITIVE it will be advisable to clean the booth and sludge pit. Replace the booth water with fresh industrial water. Start circulation BOOTH ADDITIVE is added to a turbulent part of the system at the rate of 3 kilograms/KL. Circulation is continued for a few minutes until all the power is dissolved, the booth is then ready for use.

The BOOTH ADDITIVE denaturing system which has the following benefits:

2.3 TACKY COAT - For Spray Booth Walls & Flash off Zone

TACKY COAT is a clear solution of non-drying varnish, specially formulated for application to spray booth walls by brush or spray. The film does not completely dry out therefore it has a tacky surface which collects and holds dust and thus greatly assists in keeping the spray booth area free from airborne dust particles and over spray.

TACKY COAT is a clear solution of non-drying varnish, specially formulated for application to spray booth walls by brush or spray. The film does not completely dry out therefore it has a tacky surface which collects and holds dust and thus greatly assists in keeping the spray booth area free from airborne dust particles and over spray.

When contaminated wih dust or over spray, the TACKY coating can be easily washed off with MTO or Kerosene. A fresh coat of TACKY COAT can be appied to the both walls.

TACKY COAT is easily removed from booth walls by washing with MTO, it is very easily soluble. Where paint overspray is landed on the booth wall as a thin mist of paint, it will be possible to wash away the underlying TACKY COAT film to obtain a clean wall. When paint overspray forms a complete paint film on the booth wall is much more difficult to wash away the underlying TACKY COAT because there is no access for the solvent to dissolve the TACKY COAT film.

Application: TACKY COAT is suitable for application to most spray booth, flash off zone, steel, Galvanized and suitably painted surfaces.

In spray - bake booths where temperatures 80°C are regularly attained, the TACKY COAT will need to be replaced more often. The coating will retain its yellowish color for a long time but it will gradually lose its tackness. When tackness is gone it can be over coated with fresh coat of TACKY COAT may be applied.

Thin layer of Coating is sufficient to hold dust particles. Excess application will not cause any harm except that the coating will sag and run from vertical walls. For application by brush, use paint brush or paste brush apply a thin coat only, to avoid runs. By roller, a single coat is adequate. Wash out equipment with MTO.

Thin layer of Coating is sufficient to hold dust particles. Excess application will not cause any harm except that the coating will sag and run from vertical walls. For application by brush, use paint brush or paste brush apply a thin coat only, to avoid runs. By roller, a single coat is adequate. Wash out equipment with MTO.

The ability to call on this expertise and knowledge has resulted in the development of the TACKY COAT, which has the following benefits.

2.4 TACKY SURFACE COATING - Water Washable Coating for Booth Walls

TACKY SURFACE COATING is a clear aqueous solution of resins and tackfires, specially formulated for application to spray Booth walls by or spray. The film does not completely dry out therefore it has a tacky surface which collects and holds dust and thus greatly assists in keeping the spray booth area free from airborne dust particles and over spray. When contaminated with dust or over spray, the TACKY SURFACE COATING can be easily washed off with water. A fresh coat of TACKY SURFACE COATING can be applied to the booth walls.

TACKY SURFACE COATING is a clear aqueous solution of resins and tackfires, specially formulated for application to spray Booth walls by or spray. The film does not completely dry out therefore it has a tacky surface which collects and holds dust and thus greatly assists in keeping the spray booth area free from airborne dust particles and over spray. When contaminated with dust or over spray, the TACKY SURFACE COATING can be easily washed off with water. A fresh coat of TACKY SURFACE COATING can be applied to the booth walls.

TACKY SURFACE COATING is easily removed from booth walls by washing with water, it is very easily soluble. Where paint overspary is landed on the booth wall as a thin mist of paint, it will be possible to wash away the underlying TACKY SURFACE COATING film to obtain a clean wall. When paint overspray forms a complete paint film on the booth wall is much is much more diffcult to wash away the underlying TACKY SURFACE COATING because there is no access for the water to dissolve the TACKY SURFACE COATING film.

Application at Room Temperature:

TACKY SURFACE COATING is suitable for application to most spray booth surfaces including steel, Galvanized and suitably painted surfaces. Suitable painted surface are 2 pack polyurethane, 2 pack epoxy or other stoved paints which may be used in spary booths. Only a thin film of TACKY SURFACE COATING is required to protect booth walls. It is reasonable to except 10-12 Square meter / liter. After the water has evaporated away the tacky coating should be 10-20 micron thick (by calculation). In case tack is not sufficient, second coat may be applied to improve tack.

The coating will retain its pale color for a long time but it will gratually lose its tackness. When tackness is gone it can be over coated with fresh TACKY SURFACE COATING to restore the tack or the booth wall can washed down and fresh coat of TACKY SURFACE COATING applied.

By spray, use a spray gun nozzle 0.6 - 1.7 mm. A small amount of TACKY SURFACE COATING is suffcient & only a thin film is required. Excess application will not cause any harm except that the coating will sag and run from vertical walls. For application by brush, use paint brush or paste brush apply a thin coat only, to avoid runs. By roller, a single Coat is adequate. Wash out equipment with water.

The ability to call on this expertise and knowledge has resulted in the development of the TACKY COAT, which has the following benefits.

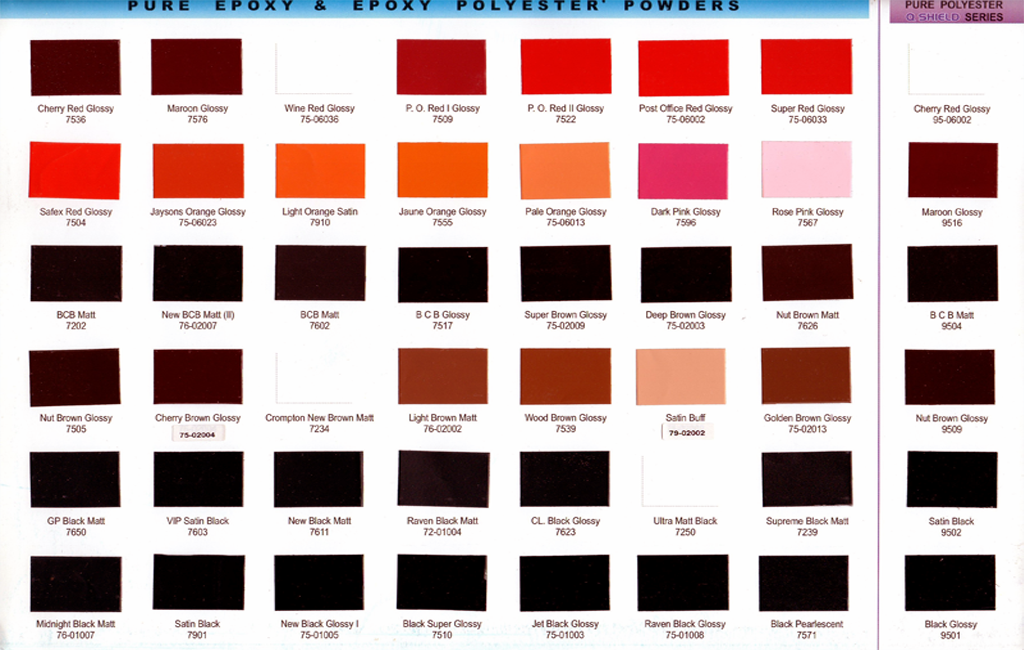

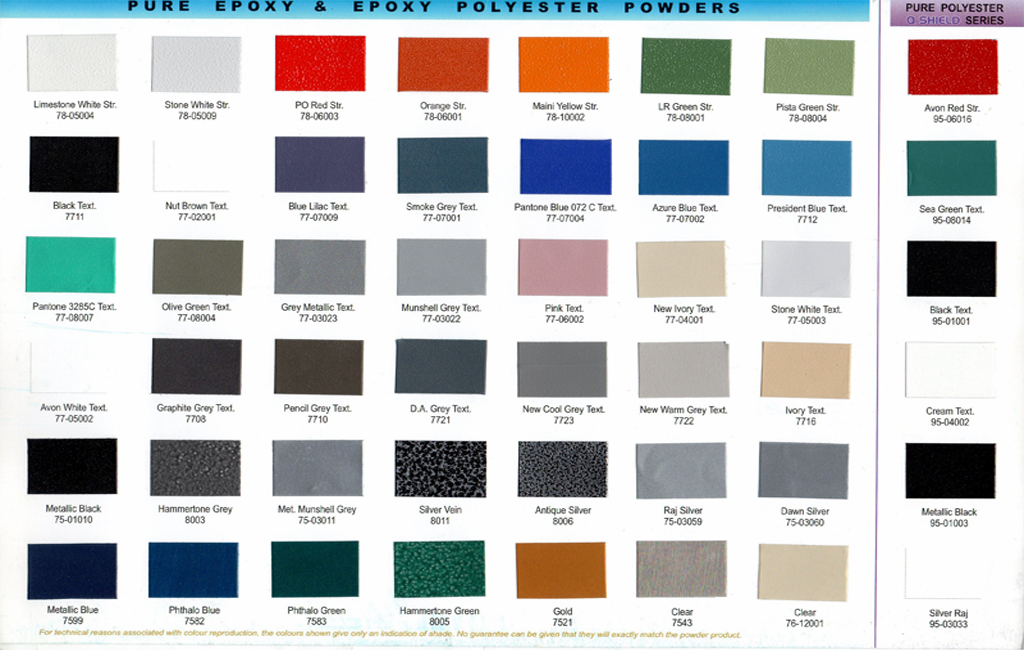

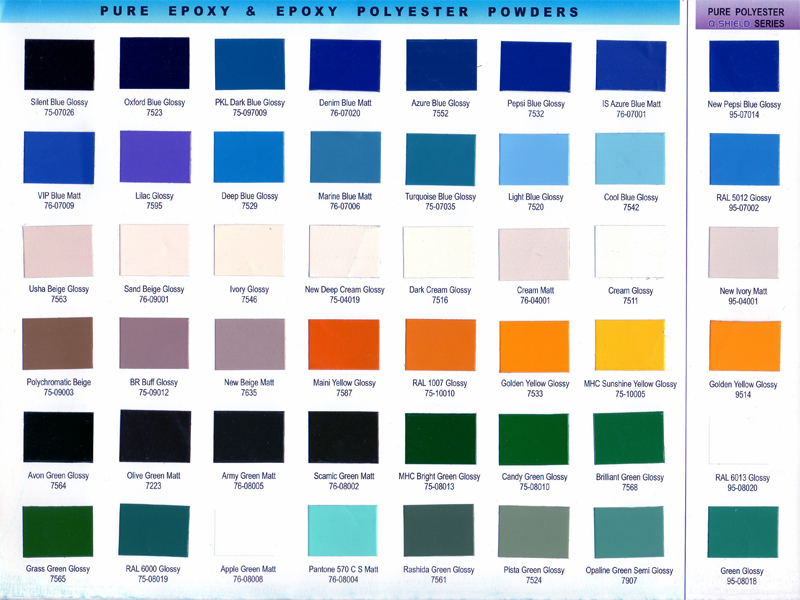

Choosen from a colour palette of over 1200 shades in Epoxy, Epoxy Polyester and Pure Polyester products has the capability to customize any shade, meeting either national / international colour standards lke IS/RAL/PANTONE.

Choosen from a colour palette of over 1200 shades in Epoxy, Epoxy Polyester and Pure Polyester products has the capability to customize any shade, meeting either national / international colour standards lke IS/RAL/PANTONE.