Turnkey Projects & Equipments

Kayvee Sales Corporation, Bangalore - one of the leading Authorized Distributors & Dealers for wide range of Turnkey Projects and Equipments - Pretreatment Plant, Powder Coating Plant, Painting Plant, Varnishing Plant.

We also offer Perfect finish, Precise dimension, Robust construction MS Tanks - which are used in several industries such as dairy, pharmaceutical and food processing for storing several liquid items at a desired temperature, Light weight PP Tanks - is ideal for storing highly corrosive chemicals, acids, waste, leach ate or pickling purposes & in large applications in Pharmaceutical and food industries to store Slurries and Pastes and Temperature resistance Self Reinforced Polypropylene Tank - is widely appreciated for various attributes such as sturdy construction, low maintenance, excellent performance, longer service life and many more.

Accessories Available: Inlet and Outlet Connection, Inbuilt fume exhaust system and scrubber, Air Agitation System, Lifting arrangements, Compartment/Partitions, Reinforcement-External, Top cover, Overflow partition (weir), Liquid Circulation System, Flanges, Plastic piping & Heater Mounting.

1. Polypropylene (PP) Tanks

Polypropylene Tanks are thermoplastic tank used as a replacement of MS, MS+FRP & PPGL+FRP tank. Tank has been designed by special engineering software to get optimum thickness of PP sheet & optimum requirement of stiffneres, resulting into optimum cost.

Why PP Tank?: Welded with the Hot Gas Extrusion welding Process, 100% Leak proof, Corrosion free, Environment friendly fume removal, system, available with connection like drain / overflow, Repairable, Acid/Alkali chemical resistant.

PP Tank Usage: As Pickling tank, Pickling tank for galvanizing tank, Electroplating tank, Circulation tank, Treatment tank, Passivation tank, Rinse tank, Mixing tank, Etching tank, Metering tank, Effluent tank, Stirrer vessel, Cooling tank, Pre & Post treatment tank, Storage tank, Waste water tank, Washing tank, Pickling tank for SS plates / strips, Pickling tank for SS pipe, Developing tank, Anodizing tank, Overflow tank, Chemical process tank, Auxiliary process tank, 7 Tank teatment plant, Acid storage tank, Primary tank, Secondary tank, dM water tank and Filter tank.

Accessories Available with PP Tank: Top Cover/Lid • Accessories like drain, Overflow, Inlet • Exhaust & Scrubber System • Overflow Partition (weir) • Lifting Arrangement • Air Agitation System • Liquid Circulation System • Legs/Mounting • Flanges • With External Reinforcement • Plastic Pipings • Compartment / Partitions

2. Electroplating Equipments

Kayvee Sales Corporation offer wide range of Electroplating Equipments which includes Oblique Planting Barrel, Fully Immersed Barrel, Oblique Tumbling Barrel, Bottom Emptying Electrically Heated Centrifugal Dryer, Agitation Unit, Exhaust Equipment and Portable Plating Barrel etc.

2.1 Portable Plating Barrel

The bulk plating of the small articles ie. barrel plating has been considered the most economical method because of low labour cost and the elimination of racking and rack maintenance.

This is a portable type of plating barrel, constructed of specifically treated plastic for operating in a higher temperature.

This portable barrel can be operated single handed for continuous production through hot alkaline cleaners, water rinses, acid dips and alkali plating processes including stannate tin.

Cathode contacts are of flexible type, designed to give effective current distribution and can be readily removed for stripping. Panels of plating cylinder are drilled with such diameter of holes giving approximately 20% open area. This feature coupled with the design of the electrical equipment results in extra fast plating production.

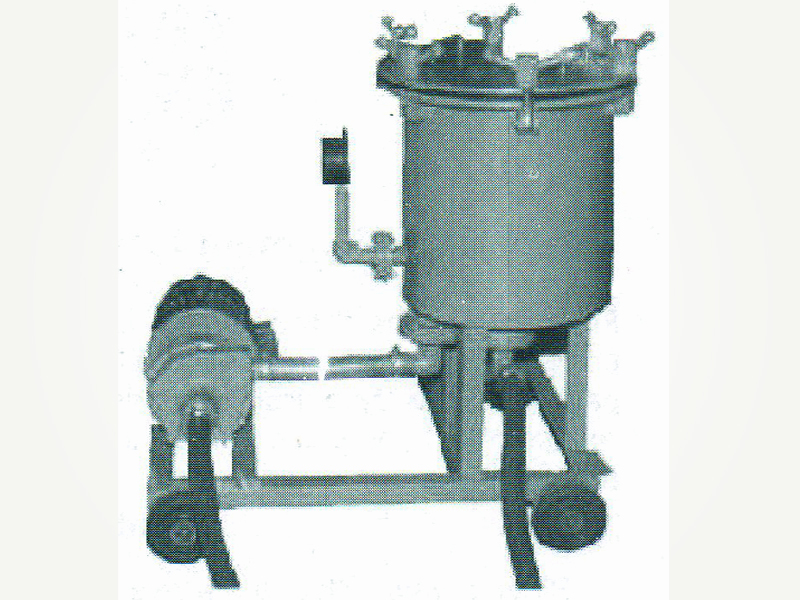

2.2 Filter Units

This totally enclosed filter unit, as illustrated, consists of disc type filter elements pack, monoblock pump body and PP lined container mounted on the wheeled trolley. This unit is suitable for acid and alkaline solutions having temperature upto 90°C, with exception of CHROME.

The components of the filter unit, which remain in contact with acid and alkaline solutions are of rubber, plastic and stainless steel to resist the corrosion action.

Cotton, nylon and terylene can be used as filter cloths. The filter units are available in four capacities of 9000, 4500, 2250 and 1350 Liters/hour.

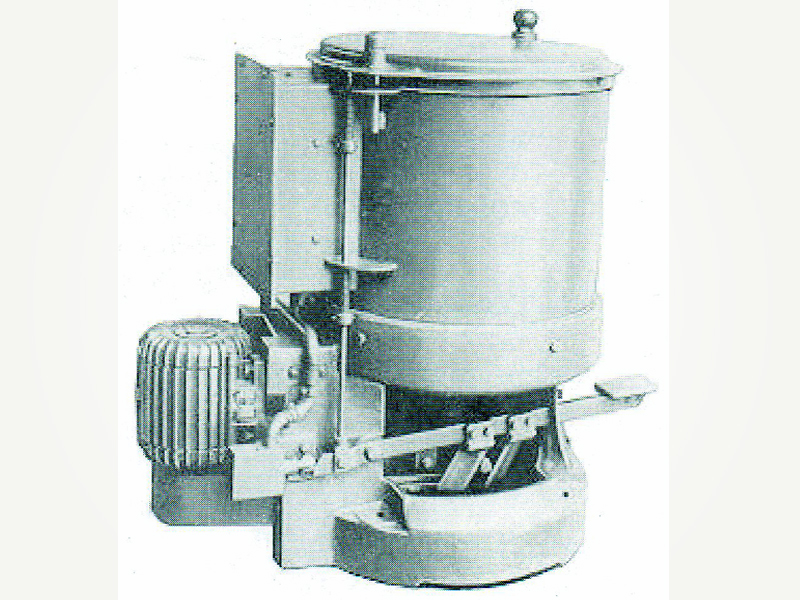

2.3 Electrically Heated Centrifugal Dryer

To speed up production in plating works, the need to dry the work arises. This electrically heated centrifugal dryer is of robust construction with sheet metal outer container mounted on heavy cast-iron base to provide stability when the work loads are out of balance. The perforated basket can be taken out of the dryer for loading and unloading of the aricles.

To allow for wear the break shoe lining there is a provision for simple adjustment. The electric heaters are contained in a box. The heating elements are replaceable.

The perforated basket and the fly wheel are balanced to minimize the vibrations.

2.4 Fully Immersed Barrel

The fully submerged motorized barrel is designed for handling of small articles such as screws, rivets, nuts etc.

The unit is suitable for the most deposits with the exception of chrome. The unit is equipped with all plastics perforated battle, bearings, gear ring and the side panels which remain in the solution.

The rotary, stationery bearings and the plastic gear ring is replaceble. Barrels are available in three capacities.

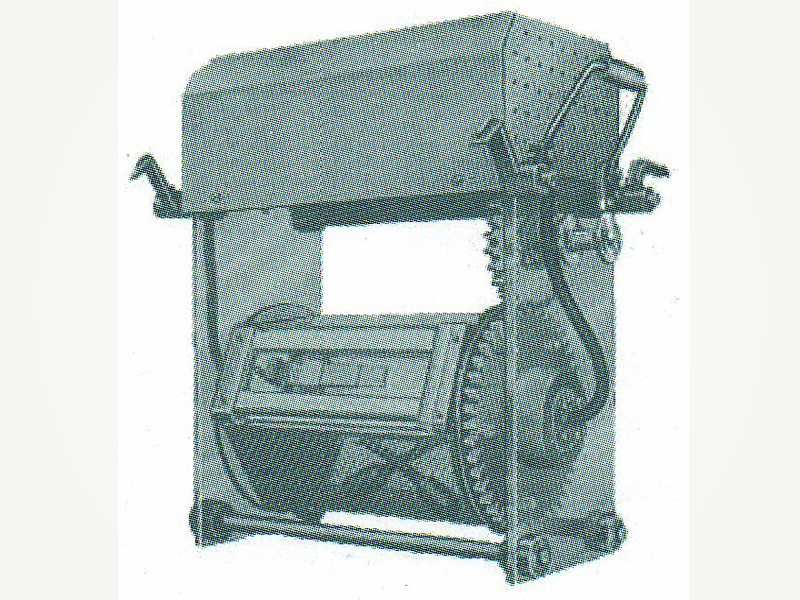

2.5 Oblique Plating Barrel

The machine is an oblique type of tilting rubber lines steel barrel, as illustrated, is designed for the rapid and efficient handling of small articles that cannot be treated in perforated barrel.

This barrel is suitable for the most deposits with the exception of chrome. The barrel is tilted with handwheel operated by sector-pinion arrangement and is rotatable during emptying to discharge the plated articles.

The anode is carried on a cast bracket, which can be adjusted in any position, it can easily be detached for emptying the barrel.

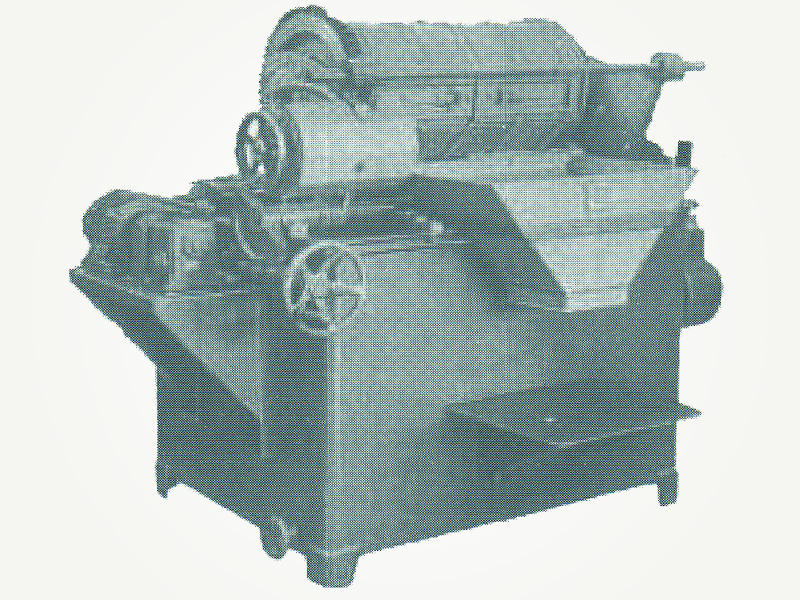

2.6 Oblique Tumbling Barrel

The Oblique Tumbling Barrel is for deburring and finishing operations of small articles, made of metal, plastic, ebonite and wood.

This heavy duty oblique tumbling barrel, as illustrated, is of robust construction of cast-iron frames of rigid sections coupled together with stout tie-bars. The barrel can be constructed in mild steel rubber lined mild steel and wood.

This tumbling barrel is tilted by means of sector-pinion mechanism for emptying the finished articles, and can be kept at any desired tilt-angle to suit better polishing.

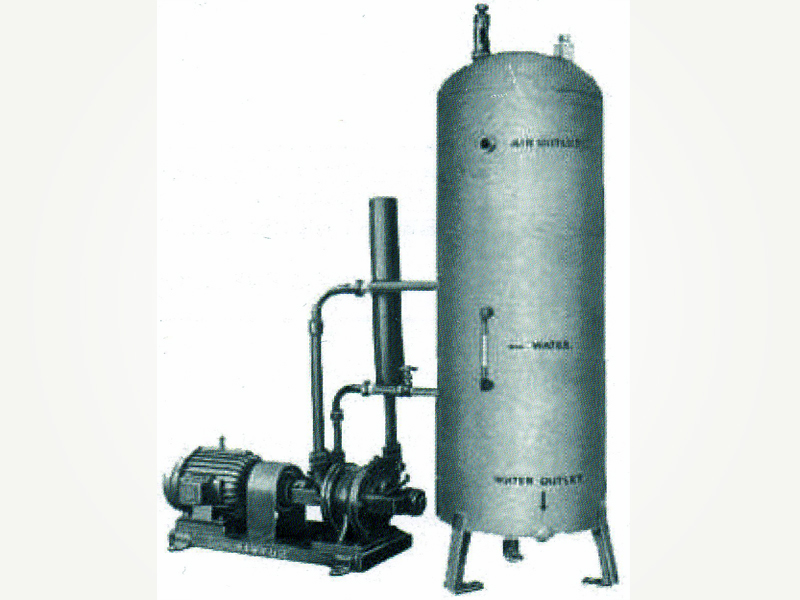

2.7 Agitation Unit

This is a rotary air unit, complete with air vessel, fitted with safety valve, pressure gauge and water guage, It provides clean, water washed air for agitation and does not require oil for lubricated by the circulation of water. On account of this, danger of contamination of plating solution with automized oil of air, is avoided, because Industrial reciprocating air compressor generally given oil mixed air.

The air receiver vessel is not dip galvanized to resist against the rusting.

Rotary air units are available in four capacities.

2.8 Bottom Emptying Electrically Heated Centrifugal Dryer

The dryer is constructed of two main MS channel section supports, at sides and heavy duty MS chamber of the dryer is mounted.

The perforated basket is rotated vertically by shaft filled in taper rubber cone bush which holds the main MS bearing housing and due to the taoer rubber cone the verticle shaft of the basket is swinging to take the vibrations during rotation.

The articles which are to dried, are to be fed in the basket by opening the lid, provded on the top of the contained, and the dried articles are emptied from the bottom of the basket by merely pressing the handle-lever provided on the top of the machine.